Innovative, circular, and regenerative!

Viscose

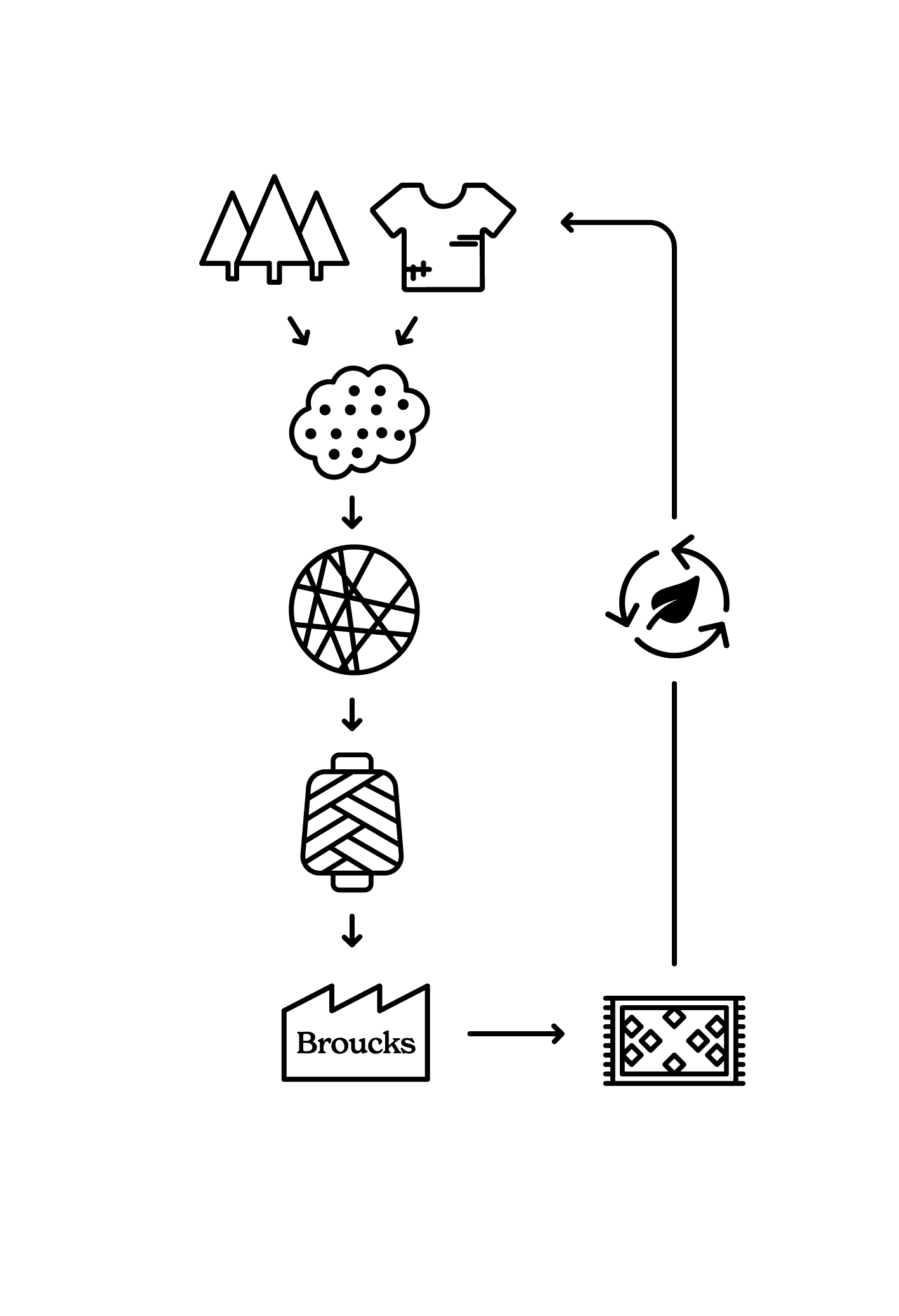

Unlike most manmade fibres viscose is non synthetic as it is made from wood pulp which comes from fast growing regenerative trees and plants.

Viscose is thus made of cellulose, the most abundant organic material in the world. This give viscose the following crucial advantages over synthetic yarns: it comes from a non-exhaustible source and it is biodegradable.

Viscose nowadays is produced in a “closed-loop” system, which captures/neutralizes/re-uses the nasty chemicals and treats the water so there is no water pollution.

But the development we are following with the most interest is the one in which used garments and textile production waste with high cellulosic content, like cotton or viscose, are shredded, de-buttoned, de-zipped, de-coloured and turned into a pulp. This pulp is then purified from containments and non-cellulosic content and is fed back into the textile production value chain as a replacement for virgin materials like cotton, oil and wood. This evolution is still in its infancy but is moving forward at a rapid pace to become truly industrialized.

Non-exhaustible and biodegradable.

Recycled cotton

Our recycled cotton weft is made from pre-consumer textile waste coming from garment production and other spinning waste as the main raw material.

This waste gets shredded, blended with another recycled fibre for strength and colour, and spun into yarn on specialised open-end machines.

The great advantage of this recycling process is that a large proportion of the pre-consumer textile waste does not end up in landfill and by blending different colours of waste we get a recycled yarn that can be produced without water, dyes or chemicals.

Our own waste flows

In our own organisation too, we try to map out our waste flows as accurately as manageable.

We work hard to keep all waste streams separated so that we can go as far as possible towards recycling and reusing residual products , and as little as possible to disposal.